ARC2300

Keyword :

ARC2300

- Generalinfo

- Technical specifications

- Picture

- video

- 型号参数

-

Background

ANRUI Intelligent Pin/Bolt Remover aims to solve this kind of problems. Hydraulic driven ensure the disassemble power

10times of hand impact way at least. Max 500 times impact without pauses or rest, greatly enhance the work efficiency for

customers.

Featured and Advantage

Innovative Design

Enable stepless frequency adjustment for more intuitive and effortless operation.

Advancee Process

Explorsive hydraulic breaker with independent IP rights achieves truely recoil-free performance

New Material

Customized materials extend service life, ensuring refined durability and reliability

Low Energy Consumption

Tasks previously requiring multiple operators can now be handled easily by single person

Low Failure Rate

Lightweight design with minimal malfunction occurrences

Reduce Investment

High efficiency lowers operation cost and investment

-

Technical data of the ANRV Bolt Remover

Model Unit ARC1500 ARC2300 Impact Energy J 1000~1500 1600~2300 Impact Frequency bpm Adjustable 1-500 Impact Rod Diameter mm ≤φ85 ≤φ100 Weight kg ≤450 ≤650 Pin/Bolt Diameter mm 32~180 32~200 Hydraulic Station Technical data

Working Pressure Mpa ≤8-12 ≤12-13 Working Flow L/ min ≤100-110 ≤120-130 Motor Power KW 18.5 30 Voltage V/HZ/P 380V/50HZ/3PH(Customized) Oil Tank Volume L 180 200 System Supply Own Prepare/ANRV customized -

Model Unit ARC2300 Impact Energy J 1600~2300 Impact Frequency bpm Adjustable 1-500 Impact Rod Diameter mm ≤φ100 Weight kg ≤650 Pin/Bolt Diameter mm 32~200

Product Introduction

| Model | Unit | ARC2300 |

| Impact Energy | J | 1600~2300 |

| Impact Frequency | bpm | Adjustable 1-500 |

| Impact Rod Diameter | mm | ≤φ100 |

| Weight | kg | ≤650 |

| Pin/Bolt Diameter | mm | 32~200 |

Background

ANRUI Intelligent Pin/Bolt Remover aims to solve this kind of problems. Hydraulic driven ensure the disassemble power

10times of hand impact way at least. Max 500 times impact without pauses or rest, greatly enhance the work efficiency for

customers.

Featured and Advantage

Innovative Design

Enable stepless frequency adjustment for more intuitive and effortless operation.

Advancee Process

Explorsive hydraulic breaker with independent IP rights achieves truely recoil-free performance

New Material

Customized materials extend service life, ensuring refined durability and reliability

Low Energy Consumption

Tasks previously requiring multiple operators can now be handled easily by single person

Low Failure Rate

Lightweight design with minimal malfunction occurrences

Reduce Investment

High efficiency lowers operation cost and investment

Technical Specifications

Technical data of the ANRV Bolt Remover

| Model | Unit | ARC1500 | ARC2300 |

| Impact Energy | J | 1000~1500 | 1600~2300 |

| Impact Frequency | bpm | Adjustable 1-500 | |

| Impact Rod Diameter | mm | ≤φ85 | ≤φ100 |

| Weight | kg | ≤450 | ≤650 |

| Pin/Bolt Diameter | mm | 32~180 | 32~200 |

Hydraulic Station Technical data

| Working Pressure | Mpa | ≤8-12 | ≤12-13 |

| Working Flow | L/ min | ≤100-110 | ≤120-130 |

| Motor Power | KW | 18.5 | 30 |

| Voltage | V/HZ/P | 380V/50HZ/3PH(Customized) | |

| Oil Tank Volume | L | 180 | 200 |

| System Supply | Own Prepare/ANRV customized | ||

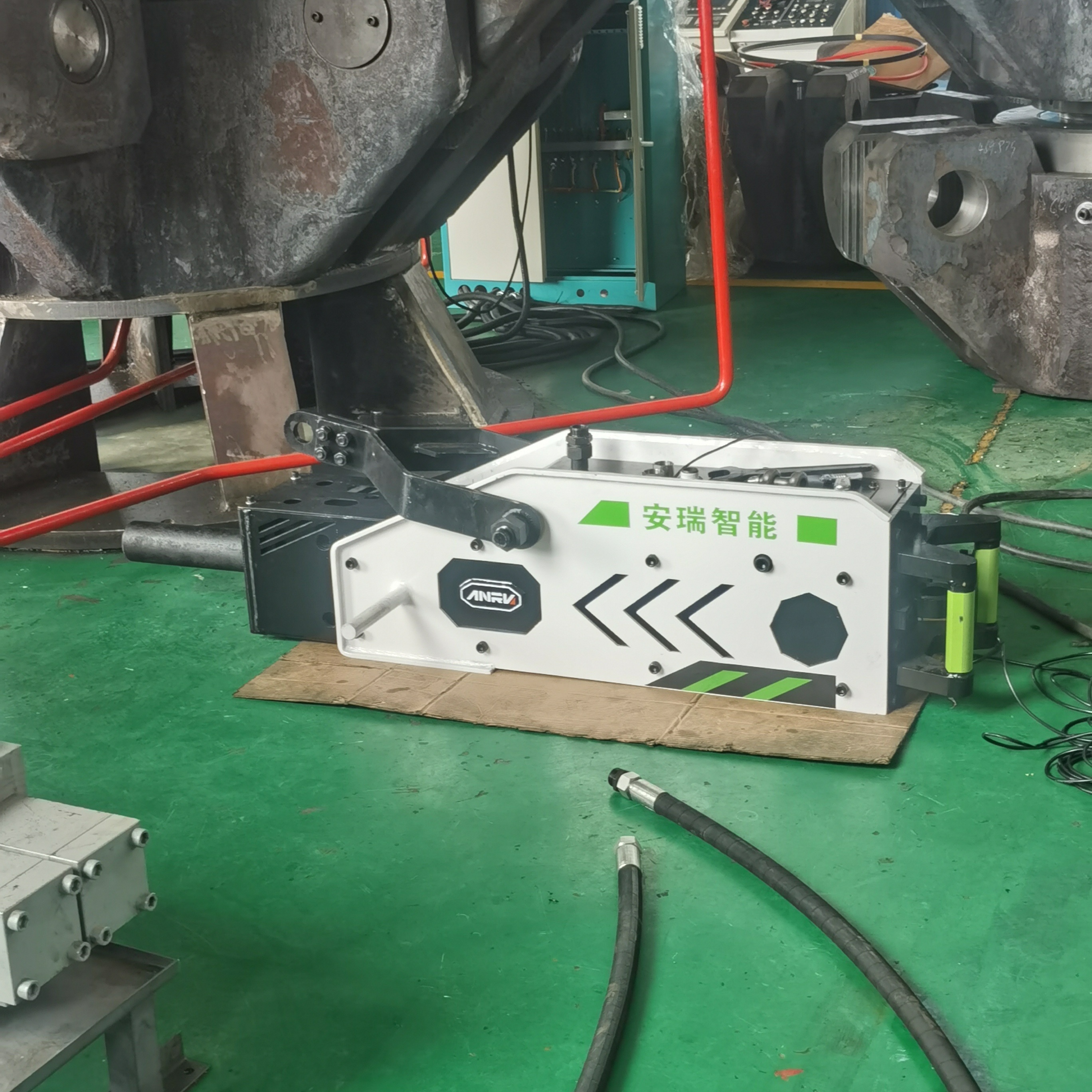

Picture

Video

Keyword :

ARC2300

Product Inquiry

We will contact you within one working day. Please pay attention to your email.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Related Products