Aug 12,2025

Hydraulic Breaker AR68 Innovations and Technical Overview for Heavy-Duty Demolition

ANRV Hydraulic-Nitrogen combined Hydraulic Breakers AR68

ANRV AR68 hydraulic-Nitrogen combined breakers

Hydraulic breakers are indispensable tools in construction, mining, quarrying, and demolition industries. Designed to efficiently demolish concrete, asphalt, rock, and other hard materials, hydraulic breakers convert hydraulic energy from carrier machinery into powerful impacts through a tool bit. Among various models engineered for diverse applications, the AR68 stands as a technologically advanced hydraulic breaker that combines durability, efficiency, and operational flexibility.

This article presents an in-depth technical analysis of the AR68 hydraulic breaker, exploring its engineering design, performance parameters, maintenance features, and practical applications. Through detailed discussion and data-driven insights, the AR68’s position as a reliable and powerful demolition tool will be comprehensively demonstrated.

Principles of Hydraulic Breaker Operation

A hydraulic breaker works by using hydraulic oil pressure from the carrier (normally excavator,sometimes another construction machines) to propel the piston inside the cylinder, the piston strikes the chisels repeatedly at suitable speed, generating impact energy to break or demolish these rocks, concreate and buildings.

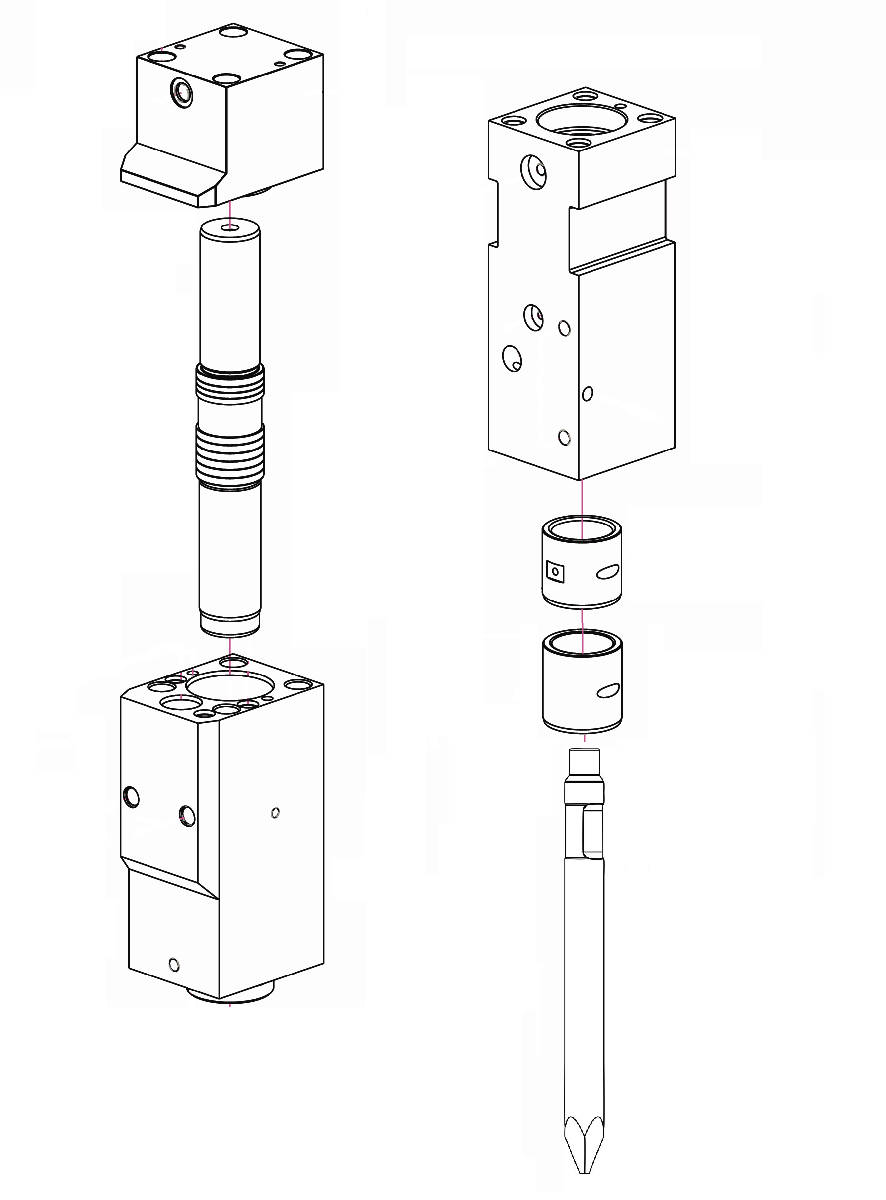

The core components involved include:

- Hydraulic Circuit: Transfers pressurized fluid from the carrier to the breaker. manufactured inside the Cylinder

- Cylinder: The main components, where the piston lay in.

- Piston: Moves linearly under hydraulic pressure to deliver impact.

- Front Head: the front part of the hydraulic breakers mainbody, there are bushes and chisels inside

- Chisel: The working tip that contacts the material.

- Nitrogen Gas Chamber: Absorbs recoil and controls piston return speed.

- Accumulator and Seals: Maintain hydraulic balance and prevent fluid leakage.

- ∗ AR68 no accumulator

The AR68 optimizes these elements to deliver consistent, high-energy impacts while protecting the carrier and operator from excessive vibration and wear.

Key Technical Specifications of AR68

The AR68 is designed for heavy-duty applications and compatible with carriers in the 4 to 6 ton carriers. Below is a detailed specification table outlining its main technical parameters:

Model | Unit | AR68 | |

Tool Diameter | mm | 68 | |

Suitable Carrier | ton | 4.5-6 | |

Weight | Side | kg | 285 |

Top | kg | 296 | |

Box | kg | 362 | |

Working Flow | L/ min | 40-70 | |

Working Pressure | bar | 110-140 | |

Nitrogen Pressure | bar | 12-15 | |

Impact Energy | J | 540 | |

Impact Frequency | bpm | 500-900 | |

This data indicates that the AR68 operates efficiently within a broad pressure and flow range, allowing operators to adjust performance based on task requirements. Its impact energy and frequency range suit diverse demolition scenarios, from breaking concrete slabs to quarry rock fragmentation.

Design Innovations and Engineering Excellence

1. Advanced Hydraulic System

The AR68 integrates a high-efficiency hydraulic system that minimizes internal losses and maximizes energy transfer. Precision-machined valves and pistons ensure optimal fluid control, while the hydraulic circuit is designed to reduce heat generation and maintain stable pressure.

2. Reinforced Tool Steel

The chisels and housing components are manufactured using specialized high-strength steel alloys. Heat treatment processes improve wear resistance, toughness, and fatigue strength, extending the service life under demanding field conditions.

3. Nitrogen Gas Chamber Technology

A pressurized nitrogen gas chamber cushions the piston’s recoil and controls the return speed, mitigating shock loads transferred to the carrier. This technology reduces machine vibration, prolongs carrier lifespan, and enhances operator comfort by reducing fatigue.

4. Modular Component Architecture

The AR68 features a modular design that simplifies maintenance and repair. Key components such as the Chisel, piston, bushings, and seals can be individually replaced without complete disassembly, reducing downtime and operational costs.

Operational Efficiency and Performance

The AR68 hydraulic breaker offers flexible operation through adjustable impact frequency and blow energy, allowing operators to fine-tune performance according to material hardness and project needs. The hydraulic flow and pressure can be varied within the recommended ranges, optimizing fuel consumption and reducing stress on carrier machinery.

An important performance metric is the impact energy, measured in Joules, which directly correlates with the breaker’s ability to fracture materials. The AR68’s impact energy range of 540 Joules enables it to handle all kinds of heavy demolition tasks efficiently.

Applications in Industry

The AR68 hydraulic breaker is widely applied in various sectors:

- Construction: Efficiently demolishes concrete structures, foundations, and walls.

- Mining and Quarrying: Breaks down rocks and boulders for easier transportation and processing.

- Road Maintenance: Removes old asphalt and concrete during repair works.

- Civil Engineering: Used for trenching, excavation, and other site preparation activities.

Its compatibility with excavators and backhoes in the 8 to 12-ton class makes it a versatile solution for contractors and heavy machinery operators.

Maintenance and Safety Considerations

Proper maintenance ensures maximum availability and long service life of the AR68. Scheduled inspection of seals, bushings, and tool condition is critical. The modular design allows quick access to wear parts, facilitating routine upkeep.

Safety features include:

- Protective guards to shield operators from flying debris.

- Noise reduction technologies to comply with workplace regulations.

- Vibration dampening systems to prevent operator fatigue and potential health issues.

Operators should also ensure hydraulic oil cleanliness and use recommended filtration to prevent internal component damage.

Comparative Advantage: AR68 vs. Conventional Breakers

Compared to conventional breakers of similar size, the AR68 delivers higher impact energy and improved durability due to its advanced material selection and hydraulic design. Its gas chamber system more effectively reduces recoil, minimizing machine wear. The automated lubrication system reduces manual servicing requirements, improving operational efficiency.

Summary Table: AR68 vs very popular same model Hydraulic Breaker Parameters

Parameter | Unit | AR68 | *B40 |

Tool Diameter | mm | 68 | 68 |

Impact Energy | J | 540 | 510 |

Operating Weight | kg | 285 | 295 |

Noise Level | dB | ≤ 105 | ≤ 110 |

Maintenance Interval | H | 500-600 | 400-500 |

Impact Frequency | bpm | 500-900 | 400-800 |

∗ Weight data from AR68 and *B40 side type breaker

This comparison highlights the AR68’s competitive performance parameters, demonstrating its engineering advancements and operational superiority.

Conclusion

The AR68 hydraulic breaker represents a high standard in demolition technology, combining robust construction, advanced hydraulic engineering, and user-oriented maintenance features. Its ability to deliver consistent, powerful impacts with reduced vibration and enhanced operator comfort makes it an essential tool in the modern construction and demolition landscape.

Through careful design and precision manufacturing, the AR68 offers operators a reliable, efficient, and versatile solution for a wide range of heavy-duty breaking applications. As industries demand increasingly sophisticated equipment, models like the AR68 set the benchmark for performance and durability.

The AR68 hydraulic breaker offers advanced impact energy, durability, and efficiency for medium to heavy-duty demolition and construction applications.

Hydraulic Breaker